Services

Applications in microdispensing are usually very complex.

Not only the chemical and physical properties of a liquid need to be considered –

also the interaction of the liquid with substrates and the demands of the application process are affecting the quality of the results.

For optimal solutions microdrop Technologies offers a number of lab and engineering services.

liquid tests

For evaluation of the applicability and capability of the Microdrop Technology a Microdrop Liquid Test is recommended.

This test will investigate the following:

- basic dispensing possibility of the fluid

- selection of the best dispenser head

- configuration performance of the dispensing

- process max. / min. dispense frequency

- droplet velocity

- optimal nozzle diameter

- driving parameters of the dispenser head

- special characteristics and handling options which need to be considered

(e.g. drop shape, light sensitivity)

application tests

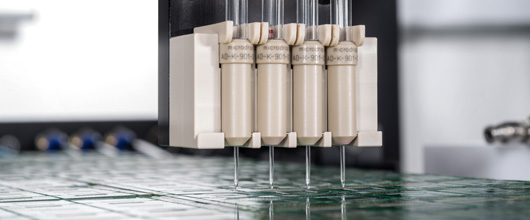

After the Microdrop Liquid Test has proven that the material is dispensable by one of the microdrop products, additional application and prototyping tests may be carried on. The investigations in the Microdrop Lab are aiming at optimal solutions for individual application needs and optimal processes. Here the material is deposited on test substrates or components and the whole process including the interaction between material and substrate is investigated; e. g.:

- wetting behavior

- drying effect

- line spreading

- structure building (e. g. line width, thickness, height)

- interconnection (e. g. bonding application)

- process parameters (e. g. temperature conditions, cycle time, throughput)

The Application Test provides an optimized production process or handling instructions about the investigated application. The dispensing system best fitted for the application will be finally identified.

customer training

For an easy start we offer training considering the customer’s individual needs on the Microdrop Systems. Each training is tailored for special demands related to the customer`s application. Whether the applications are originated from production or R&D activities, users are instantly able to start their application after training and assistance by the skilled Microdrop Team.

strategic partnership

The dispensing products from microdrop Technologies provide a high potential of applications in modern areas like material sciences, micro- and nanotechnology as well as life science. As a result, new products are arising. Therefore new technologies and processes for material deposition and micro dispensing are required. The Microdrop Team is already working for more than 16 years in the field of micro dispensing, also in cooperation with the key players from R&D and production identifying and solving the new challenges. We invite you to share our skills and experiences based on an exclusive Strategic Partnership (focussed e.g. on a certain production step, the development of a new ink, the coating of implant materials, etc.). Combining the knowledge about microdispensing as well as inkjet technology with your expertises will lead to new solutions, production processes and products.